Insulation Resistance (IR) Values - Index

1.

IR values for Electrical Apparatus & Systems

4. IR Value for Electric Motor

5. IR Value for Electrical

cable and wiring

6. IR Value for Transmission /

Distribution Line

8. IR Value for Substation

Equipment

9. IR Value for Domestic /

Industrial Wiring

Required Precautions

|

Max.

Voltage Rating of Equipment |

Megger

Size |

Min.

IR Value |

|

250 Volts |

500

Volts |

25

MΩ |

|

500 Volts |

1,000

Volts |

100

MΩ |

|

5 KV |

2,500

Volts |

1,000

MΩ |

|

8 KV |

2,500

Volts |

2,000

MΩ |

|

15 KV |

2,500

Volts |

5,000

MΩ |

|

25 KV |

5,000

Volts |

20,000

MΩ |

|

35 KV |

15,000

Volts |

100,000

MΩ |

|

46 KV |

15,000

Volts |

100,000

MΩ |

|

69 KV |

15,000

Volts |

100,100

MΩ |

<

1KV = 1MΩ minimum

>1KV

= 1 MΩ / 1KV

As

per IE Rules-1956

At a

pressure of 1000 V applied between each live conductor and earth for a period

of one minute the insulation resistance of

HV installations shall be at least 1 Mega ohm or as specified by the Bureau of

Indian Standards.

Medium

and Low Voltage Installations- At a pressure of 500 V applied between each live

conductor and earth for a period of one minute, the insulation resistance of

medium and low voltage installations shall be at least 1 Mega ohm or as

specified by the Bureau of Indian Standards] from time to time.

As

per CBIP specifications, the acceptable values are 2 Mega ohms per KV

Insulation

resistance tests are made to determine insulation resistance from individual

windings to ground or between individual windings. Insulation resistance tests

are commonly measured directly in megohms or may be calculated from

measurements of applied voltage and leakage current.

The recommended practice in measuring insulation resistance is to always ground the tank (and the core). Short circuit each winding of the transformer at the bushing terminals. Resistance measurements are then made between each winding and all other windings

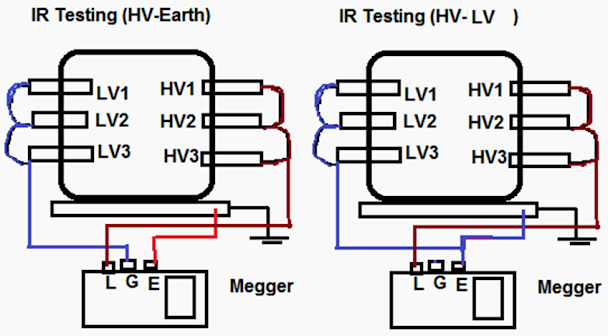

Insulation resistance testing: HV – Earth and HV – LV

Transformer windings are never left

floating for insulation resistance measurements. Solidly grounded winding must

have the ground removed in order to measure the insulation resistance of the

winding grounded. If the ground cannot be removed, as in the case of some windings

with solidly grounded neutrals, the insulation resistance of the winding cannot

be measured. Treat it as part of the grounded section of the circuit.

We

need to test winding to winding and winding to ground (E). For three phase

transformers, we need to test winding (L1, L2, L3) with substitute Earthing for

Delta transformer or winding (L1, L2, L3) with earthing (E) and neutral (N) for

wye transformers.

|

IR

Value for Transformer (Ref:

A Guide to Transformer Maintenance by. JJ.

Kelly. S.D Myer) |

|

|

Transformer |

Formula |

|

1 Phase Transformer |

IR Value (MΩ) = C X E / (√KVA) |

|

3 Phase Transformer (Star) |

IR Value (MΩ) = C X E (P - n) / (√KVA) |

|

3 Phase Transformer (Delta) |

IR Value (MΩ) = C X E (P - P) / (√KVA) |

|

Where C= 1.5 for oil filled T/C with Oil

Tank, 30 for Oil filled T/C without Oil Tank or Dry Type T/C |

|

Temperature

correction Factor (Base 20°C):

|

Temperature

correction Factor |

||

|

°C |

°F |

Correction

Factor |

|

0 |

32 |

0.25 |

|

5 |

41 |

0.36 |

|

10 |

50 |

0.50 |

|

15 |

59 |

0.720 |

|

20 |

68 |

1.00 |

|

30 |

86 |

1.98 |

|

40 |

104 |

3.95 |

|

50 |

122 |

7.85 |

Example:

For

1600kVA, 20kV/400V, Three Phase Transformer

·

IR Value at HV Side= (1.5 x 20000) / √1600 =

16000 / 40 = 750 MΩ at 20°C

·

IR Value at LV Side= (1.5 x 400) / √1600 =

320 / 40 = 15 MΩ at 20°C

·

IR Value at 30°C = 15 x 1.98 = 29.7 MΩ

Insulation

Resistance of Transformer Coil

|

Transformer

Coil Voltage |

Megger

Size |

Min.

IR Value Liquid Filled T/C |

Min.

IR Value Dry Type T/C |

|

0 – 600 V |

1

KV |

100

MΩ |

500

MΩ |

|

600 V to 5 KV |

2.5

KV |

1,000

MΩ |

5,000

MΩ |

|

5 KV to 15 KV |

5

KV |

5,000

MΩ |

25,000

MΩ |

|

15 KV to 69 KV |

5

KV |

10,000

MΩ |

50,000

MΩ |

Insulation

Resistance of Transformer Coil

|

Voltage |

Test

Voltage (DC) LV

Side |

Test

Voltage (DC) HV

Side |

Min.

IR Value |

|

415 V |

500

V |

2.5

KV |

100

MΩ |

|

Up to 6.6 KV |

500

V |

2.5

KV |

200

MΩ |

|

6.6 KV to 11 KV |

1000

V |

2.5

KV |

400

MΩ |

|

11 KV to 33 KV |

1000

V |

5

KV |

500

MΩ |

|

33 KV to 66 KV |

1000

V |

5

KV |

600

MΩ |

|

66 KV to 132 KV |

1000

V |

5

KV |

600

MΩ |

|

132 KV to 220 KV |

1000

V |

5

KV |

650

MΩ |

Steps for

measuring the IR of Transformer:

·

Shut down the transformer and disconnect the

jumpers and lightning arrestors.

·

Discharge the winding capacitance.

·

Thoroughly clean all bushings.

·

Short circuit the windings.

·

Guard the terminals to eliminate surface

leakage over terminal bushings.

·

Record the temperature.

·

Connect the test leads (avoid joints).

·

Apply the test voltage and note the reading.

The IR. Value at 60 seconds after application of the test voltage is referred

to as the Insulation Resistance of the transformer at the test temperature.

·

The transformer Neutral bushing is to be

disconnected from earth during the test.

·

All LV surge diverter earth connections are

to be disconnected during the test.

·

Due to the inductive characteristics of

transformers, the insulation resistance reading shall not be taken until the

test current stabilizes.

·

Avoid meggering when the transformer is under

vacuum.

Test conditions of Transformer for IR Test (Not Less than 200 MΩ)

Two

winding transformers

1. (HV

+ LV) – GND

2. HV –

(LV + GND)

3. LV –

(HV + GND)

Three

winding transformers

1. HV –

(LV + TV + GND)

2. LV –

(HV + TV + GND)

3. (HV +

LV + TV) – GND

4. TV –

(HV + LV + GND)

Auto

transformer (Two windings)

1. (HV +

LV) - GND

Auto

transformer (Three windings)

1. (HV +

LV) – (TV + GND)

2. (HV +

LV + TV) – GND

3. TV –

(HV + LV + GND)

For

any installation, the insulation resistance measured shall not be less than:

·

HV – Earth 200 MΩ

·

LV – Earth 100 MΩ

·

HV – LV 200 MΩ

Factors affecting on IR value of Transformer

The

IR value of transformers are influenced by

·

Surface condition of the terminal bushing

·

Quality of oil

·

Quality of winding insulation

·

Temperature of oil

·

Duration of application and value of test

voltage

·

IR between HV and LV as well as windings to

earth.

·

Minimum IR value for Tap changer is 1000 ohm

per volt service voltage.

For

electric motor, we used a insulation tester to measure the resistance of motor

winding with earthing (E).

·

For rated voltage below 1KV, measured with a

500VDC Megger.

·

For rated voltage above 1KV, measured with a

1000VDC Megger.

·

In accordance with IEEE 43, clause 9.3, the

following formula should be applied.

·

Min IR value (For Rotating Machine) = (Rated

voltage (v) / 1000) + 1

Insulation resistance

(IR) value for electric motor

|

As

per IEEE 43 standard 1974, 2000 |

|

|

IR

Value in MΩ |

|

|

IR (Min) = kV+1 |

For most windings made

before about 1970, all field windings, and others not described below |

|

IR (Min) = 100 MΩ |

For most dc armature and

ac windings built after about 1970 (form wound coils) |

|

IR (Min) = 5 MΩ |

For most machines with

random – wound stator coils and form-wound coils rated below 1kV |

Example

- 1: For 11KV, Three Phase Motor.

·

IR Value = 11+1=12 MΩ but as per IEEE43 It

should be 100MΩ

Example

- 2: For 415V, Three Phase Motor.

·

IR Value = 0.415+1=1.41 MΩ but as per IEEE43

It should be 5MΩ

·

As per IS 732 Min IR Value of Motor =

(20XVoltage(p-p/(1000+2XKW)

IR Value of Motor as per NETA ATS 2007. Section 7.15.1

|

Motor

Name Plate

(V) |

Test

Voltage |

Min.

IR Value |

|

250 V |

500

V DC |

25

MΩ |

|

600 V |

1000

V DC |

100

MΩ |

|

1000 V |

1000

V DC |

100

MΩ |

|

2500 V |

1000

V DC |

500

MΩ |

|

5000 V |

2500

V DC |

1000

MΩ |

|

8000 V |

2500

V DC |

2000

MΩ |

|

15000 V |

2500

V DC |

5000

MΩ |

|

25000 V |

5000

V DC |

20000

MΩ |

|

34500 V |

15000

V DC |

100000

MΩ |

IR Value of Submersible Motor:

|

As

per IEEE 43 standard 1974, 2000 |

|

|

IR

Value in MΩ |

|

|

New Motor |

20

MΩ |

|

A used motor which can

be reinstalled |

10

MΩ |

|

Motor Installed in Well

(with Cable) |

|

|

New Motor |

2

MΩ |

|

A used motor which can

be reinstalled |

0.5 MΩ |

For

insulation testing, we need to disconnect from panel or equipment and keep them

isolated from power supply. The wiring and

cables need to test for each other ( phase to phase ) with

a ground ( E ) cable. The Insulated Power Cable Engineers Association (IPCEA)

provides the formula to determine minimum insulation resistance values.

![]()

R = K x Log 10 (D/d)

R =

IR Value in MΩs per 1000 feet (305 meters) of cable.

K =

Insulation material constant. (Varnished, Cambric =2460, Thermoplastic, Polyethylene

= 50000, Composite Polyethylene=30000)

D = Outside diameter of conductor insulation for single conductor

wire and cable (D = d + 2c + 2b diameter of single conductor cable)

d – Diameter of conductor

c – Thickness of conductor insulation

b – Thickness of jacket insulation

HV test on new XLPE cable (As per ETSA Standard)

|

Application |

Test

Voltage |

Min.

IR Value |

|

New cables – Sheath |

1

KV DC |

100

MΩ |

|

New cables – Insulation |

10

KV DC |

1000

MΩ |

|

After repairs – Sheath |

1

KV DC |

10

MΩ |

|

After repairs – Insulation |

5

KV DC |

1000

MΩ |

11kV and 33kV Cables between Cores and Earth (As per ETSA

Standard)

|

Application |

Test

Voltage |

Min.

IR Value |

|

11kV New cables – Sheath |

5

KV DC |

1000

MΩ |

|

11kV After repairs – Sheath |

5

KV DC |

100

MΩ |

|

33kV no TF’s connected |

5

KV DC |

1000

MΩ |

|

33kV with TF’s connected |

5

KV DC |

15

MΩ |

0 Comments